X/B Series Cycloidal Gear Reducer

1. Size: X2 – X10, Single-stage; X31 – X128, Double-stage.

2. Ratio: 9 – 87, Single-stage; 99-7569 Double-stage

3. Rated Power: 0.18 – 43KW

4. Output torque: 26-7643N.m (Combined 29400N.m)

5. Input form: direct with motor, flange, and shaft input.

6. Mounting type: Foot, Flange.

As one of the cyclo gear reducer manufacturers, suppliers, and exporters of mechanical products, We offer cyclo gear reducer and many other products. Please get in touch with us for details.

Mail:[email protected]

X, B Series cycloidal speed reducer, also called cycloidal planetary gear speed reducer, is a novelty transmission machinery. It adapts K-H-V less differential gear epicyclic transmission principle and cycloidal pinwheel meshing. All transmission devices of epicyclic cycloidal pinwheel speed reducer can be divided into three parts: input part, slowing down part, and output part.

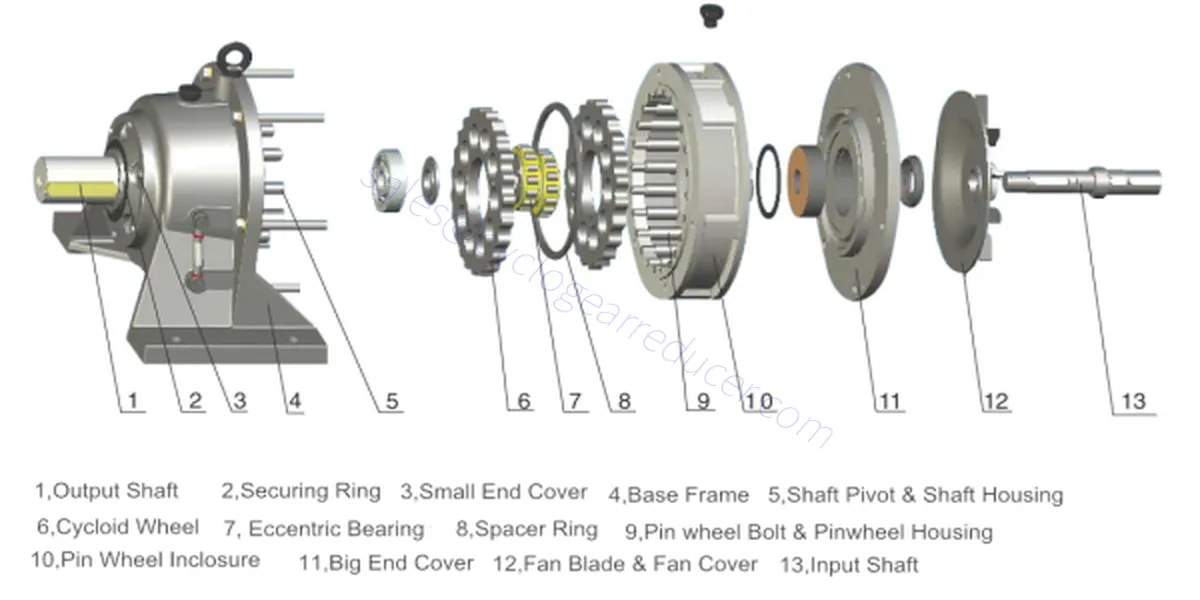

Cycloidal Gear Reducer Exploded View

Product Specifications

|

Type

|

stage

|

Model

|

Ratio

|

Nominal Power (KW)

|

Nominal Torque(N.m)

|

|

X/B Series Cycloidal Reducer |

Single reducer

|

B09/X1

|

9-87

|

0.55-0.18

|

26-50

|

|

B0/X2

|

1.1-0.18

|

58-112

|

|||

|

B1/X3

|

0.55-0.18

|

117-230

|

|||

|

B2/X4

|

4-0.55

|

210-400

|

|||

|

B3/X5

|

11-0.55

|

580-1010

|

|||

|

B4/X6/X7

|

11-2.2

|

580-1670

|

|||

|

B5/X8

|

18.5-2.2

|

1191-3075

|

|||

|

B6/X9

|

15-5.5

|

5183-5605

|

|||

|

B7/X10

|

11-45

|

7643

|

|

Type

|

stage

|

Model

|

Ratio

|

Nominal Power (KW)

|

Nominal Torque(N.m)

|

|

X/B Series Cycloidal reducer |

Double reducer

|

B10/X32

|

99-7569

|

0.37-0.18

|

175

|

|

B20/X42

|

1.1-0.18

|

600

|

|||

|

B31/X53

|

2.2-0.25

|

1250

|

|||

|

B41/X63

|

2.2-0.25

|

1179-2500

|

|||

|

B42/X64

|

4-0.55

|

2143-2500

|

|||

|

B52/X84

|

4-0.55

|

2143-5000

|

|||

|

B53/X85

|

7.5-0.55

|

5000

|

|||

|

B63/X95

|

7.5-0.55

|

5893-8820

|

|||

|

B74/X106

|

11-2.2

|

11132-12000

|

|||

|

B84/X117

|

11-2.2

|

11132-16000

|

| product name: | B / X series cycloid reducer |

| color: | Blue, silver, or customized |

| material: | Bearing steel |

| Heat treatment: | Quenching |

| Shell material | HT200 |

| Bearing material: | SKF |

| certificate: | ROHS, IS09001 |

| package: | Standard export packaging (cotton blanket + wooden box) |

| Guarantee: | One year |

| application: | Metallurgy, coal/mining industry. Cement, chemical industry, energy, Electricity, Electricity, paper industry, sugar industry, port, lifting and construction, Machinery, rubber/plastic |

Characteristics of X/B Cycloidal Speed Reducer:

(1) High reduction ratio, high efficiency. The single-stage reduction ratio is 9~87; the double-stage reduction ratio is 121~1849, the reduction ratio will be higher if adopting the third-stage reduction ratio, and cycloidal gear speed reducer efficiency can be over 90%.

(2) Adopting the compact structure of the planetary transmission part. It puts the input and output shafts on the same axis, so the cycloidal gear reducer has a compact design, midget cubage, and exceeding lightweight.

(3) Adopting scroll contact, high carbon chrome steel Gear, and quencher treatment for the main parts, the rigidity can be HRC58-65. So it has dependable durability and a long lifespan.

(4) Adopting the grease and not easy to leak oil, this cycloidal gear speed reducer can be installed in any position and angle to the user’s needs.

Application Field

Conditions of Use:

2. The rated revolution of the input shaft is 1500 revolutions per minute, and it is recommended to use a 6-pole motor with 960 revolutions per minute when the input power is greater than 18.5 KWH.

3. horizontal installation cycloid gear reducer working position is horizontal. When installing the largest horizontal tilt Angle is generally less than 15 °. Other measures should be taken in more than 15 ° guarantee adequate lubrication and prevent leakage.

4. The output shaft of cycloidal pinwheel reducer cannot be subject to larger axial force and radial force, and other measures shall be taken when there are larger axial force and radial force.

Characteristics of Transportation and Packaging:

● Short delivery period,to ensure timely delivery.

● Tight packing,to ensure the products are not damaged during transportation.

● Various modes of transportation,to ensure safe and timely transportation.

● Follow up the whole process of order,to ensure product delivery to customers.

● Long shelf life, to ensure customer experience.