XL Group

Cyclo Gear Reducer Manufacturers

Let Me Introduce

What is a cycloidal gear reducer?

Features

Characteristics of Cycloidal Reducer

High efficiency

Structure compact

Long life

Oil lubrication

Adopting the grease and not easy to leak oil, this cycloidal gear speed reducer can be installed in any position and angle to the user’s needs.

Products

Cycloidal Reducer for Sale

The following list is only a partial display of cyclo gear reducer products, and more cyclo gear reducer products are in succession on the shelves. Please contact us by email if you need to buy a cyclo gear reducer. Email: [email protected]

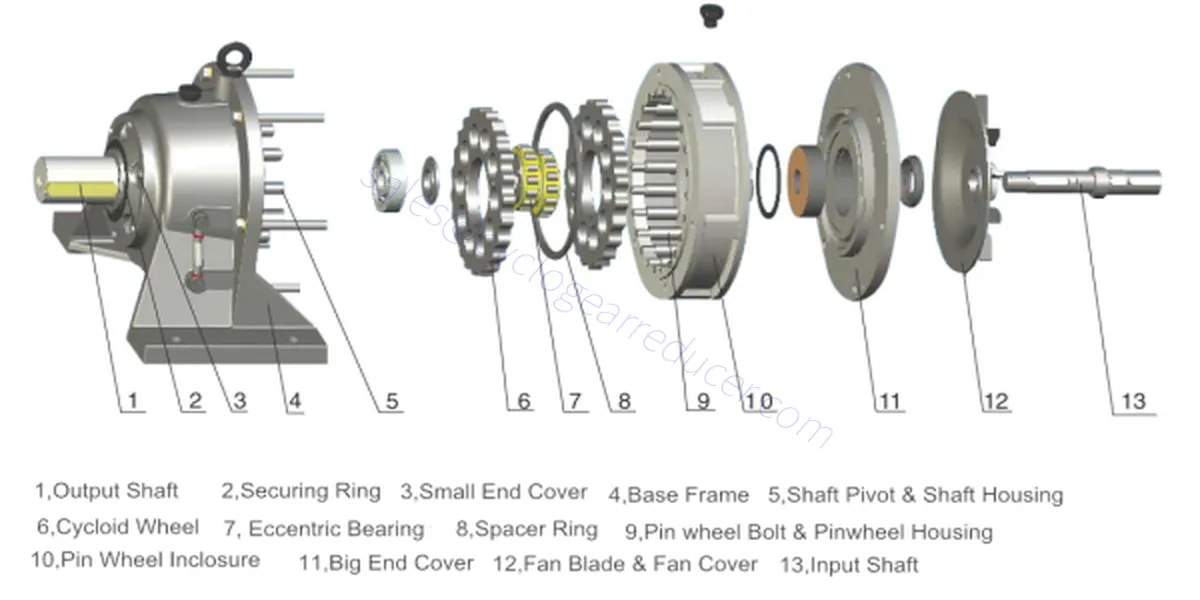

How it Works

Cycloidal Gearbox Working Principle

01

Drives A Cycloidal Disk

02

Cycloidal Disc Drives the Pin Disc

03

Transmits Very High Torque

operating temperature

The Temperature of the Cycloid Reducer

Conditions

Conditions of Use

continuous working system

- ★★★★★

The cycloidal pinwheel reducer can be used in the continuous working system while allowing both forward and reverse directions.

input power

- ★★★★★

The rated speed of the input shaft is 1500 rpm. When the input power is greater than 18.5 kW, it is recommended to use a 6-pole motor with 960 rpm.

axial and radial forces

- ★★★★★

The output shaft of the cycloid reducer cannot be subjected to large axial and radial forces. Other measures must be taken when there are large axial and radial forces.

Applications

Application Of Cycloidal Reducer

News

Learn about Cycloidal Gear Reducer

What are the requirements for the lubrication of cycloid reducer?

2. Cycloid pinwheel reducer generally chooses 40# or 50# mechanical oil lubrication at room temperature. To improve the performance of the reducer and extend the service life of the cycloid pinwheel reducer, it is recommended to use 70# or 90# extreme pressure gears. Oil lubricating oil should be reconsidered when working under high and low-temperature conditions.

3. The vertical installation of the planetary cycloid reducer must prevent the oil pump from cutting off the oil to avoid damage to the parts of the reducer.

4. When refueling, you can turn the breather cap on the upper part of the seat to refuel. When draining the oil, turn the drain plug at the bottom of the main seat to drain the dirty oil. There is no lubricating oil inside the reducer when it leaves the factory.

6. The factory-made reducer has been greased and replaced every six months.

What are the precautions for installing the cycloid reducer?

2. The output and input shaft diameters are matched with GB1568-79.

3. The eyebolts on the reducer are only for lifting the reducer.

5. When the reducer is calibrated, it can be carried out with steel or cast iron spacers. The height of the spacers is not more than three, and it can also be carried out with a contract iron, but the reducer should be replaced with flat spacers after calibration.

6. The configuration of the cushion block should avoid causing deformation of the machine body and should be arranged symmetrically on both sides of the foundation bolts. The mutual distance can be enough to allow the water slurry to flow freely during irrigation.

7. The irrigation of cement slurry should be dense, without bubbles, voids, and other defects.